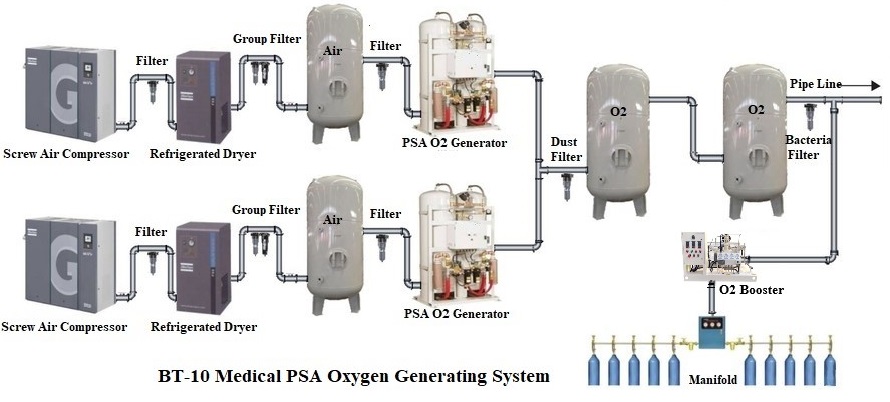

BT-10 PSA Oxygen Geneartor Parameters:

Generators Capacity: 3Nm3/h~100Nm3/h( single unit)

Oxygen Purity: 93%±3% (with PSA technology)

Power supply: 380V/220V, 50/60HZ

Out Pressure: ≥ 0.3 Mpa

Operation Noise: ≤75dB(A)

Dew Point: - 45℃

Working Principle:

Pressure Swing Adsorption (PSA) is the most commonly used, most effective for small and medium capacities oxygen production process. Our PSA units have two cylinders filled with Zeolite Molecular Sieve(ZMS). As the air flows through the cylinder, the Zeolite bed adsorbs nitrogen, while oxygen passes through to the oxygen accumulation tank. The adsorption process is interrupted before the ZMS becomes saturated with nitrogen by diverting the input air to the second cylinder, which at this point starts producing oxygen. During the regeneration process, when pressure is released into atmospheric pressure, Zeolite releases Nitrogen that was being stored on its surface. The process is repeated continuously, when one cylinder is productive, the other regenerates and at the end of each cycle they switch roles.

Features:

1. The adsorption tower adopts advanced combined coconut pad compaction technologies.

2. The advanced lotus-shaped component design fully considers and avoids the presence of high-speed impact of the gas on the molecular sieve during the adsorption process.

3. The professional blizzard combined filling technology guarantees the molecular sieve packed more uniformly and densely, ensuring that the molecular sieve does not produce a fluidity state during the adsorption process.

4. Choosing the intelligent controller of the international famous brand---SIEMENS PLC programmable controllers.

5. Adopts German imported valves, whose reaction speed is 0.02 seconds, and can continuously switch more than 2 million times under the normal condition.

6. The use of stable and excellent air source purification refrigerated air dryers and other supporting equipment, including the refrigerated air dryer, the automatic blowdown filters.

Contact: Kevin Liu

Phone: +86 18917992761

E-mail: info@bestechmed.com

Whatsapp:+86 18917992761

Add: Bldg 21, No.1800, North Sanxin Rd, Song Jiang District, Shanghai, China.